Electrostatic Spraying: New Cleaning tools for more effective disinfecting and sanitizing

Disinfecting and sanitizing of surfaces is critical to prevent the spread of illness and disease.

In schools, cold and flu season brings on a dramatic rise in absenteeism related to contagious illness. Often overlooked, pathogens such as norovirus can quickly run rampant through a school population, in some cases, it has actually caused schools to temporarily shut down.

In businesses large and small, illness related absenteeism causes companies billions of dollars each year.

In restaurants and food service operations, cleanliness and preventing foodborne illnesses are essential elements tied to the success of the business.

Disinfecting surfaces in healthcare institutions is critical to preventing healthcare associated infections (HAI). Dealing with immunocompromised patients that are more susceptible to pathogens adds to the challenge.

In the above situations, how do we insure that potentially contaminated surfaces come in contact with a disinfectant or sanitizer? And, how often do surfaces get missed that may be hidden, difficult to reach, or simply passed by due to human error?

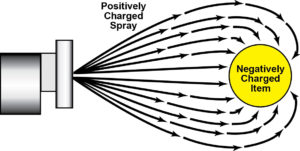

Enter electrostatic spraying of disinfectants or sanitizers. An electrostatic spray device imparts a positive electric charge to spray droplets, causing the liquid droplets to be attracted to surfaces like opposite poles of a magnet. The benefit is fast and highly uniform coverage of surfaces, including areas out of the direct line of site that might be missed by conventional sprayers.

Electrostatic spraying of disinfectants and sanitizers is new to the cleaning industry, but it is not new technology. Electrostatics have been used quite successfully in spraying of paints and coatings. It is highly useful for coating complex shapes with a highly uniform film with little or no overspray. Farmers have used electrostatic sprayers to apply pesticides to crops because of the ability to cover the top and bottom of foliage to insure complete crop protection. Electrostatic technology insures hidden or shadowed surfaces get covered with highly uniform film. Often times, up to 1/3 less solution is used to cover equal areas because waste is minimized.

Charged spray droplets are attracted to surfaces and have an enveloping effect around the object to insure all sides are covered.

The E-Spray Hand Held and Backpack electrostatic sprayers represent equipment that use electrostatic technology for the use of spraying disinfectants, sanitizers, and even odor counteractants. These devices are powered by a re-chargeable lithium ion battery. The hand held unit cartridge holds 1 quart of diluted ready to use disinfectant or sanitizer. For larger areas the Backpack units holds 9 quarts. The ease of use and portability make this device a very effective way to cover a lot of surface area quickly.

Multi-Clean offers the E-Spray Hand Held and Backpack units for use with Multi-Clean EPA registered disinfectants and sanitizers. We have validated that the Multi-Clean branded products active ingredients are not affected by the device. To insure OSHA compliance with secondary container labeling, each E-Spray unit from Multi-Clean comes with a set of secondary container labels for the validated products.

To learn more about the E-Spray System and electrostatic spraying of disinfectants and sanitizers, follow the links below:

To learn more about the E-Spray System and electrostatic spraying of disinfectants and sanitizers, follow the links below:

White Paper: Validating disinfectant activity with the E-Spray Equipment and Multi-Clean Disinfectants/sanitizers.

Literature: E-Spray from Multi-Clean

Or, visit our electrostatics webpage for more information: Multi-Clean Electrostatics

Visit us at www.multi-clean.com