E-Spray Electrostatic Disinfecting for Building Service Contractors

This article aims to stimulate value added service ideas for Building Service Contractors (BSC’s) in how they might use Electrostatic Spray (E-Spray) Disinfecting to improve results and increase revenues.

After coming off the worst Flu season in more than two decades employers, schools, hospitals, nursing homes and other public/private facilities are looking for new ways to slow the spread of contagious illnesses.

The Infographic at right from ISSA tells the story of the cost of illnesses and the consequences resulting from the lack of sanitation.

© ISSA (Infographic Courtesy of ISSA)

A building service contractor (BSC) can be an integral part of the infection control process by leveraging E-Spray technology for disinfectant application. Forward thinking Building Service Contractors (BSC’s) are always looking for ways to expand service offerings, add more value to existing services, and improve labor efficiency.

What types of accounts could a BSC target?

The simple answer is any business, organization, or institution that is financially impacted by illness related absenteeism can benefit from value added E-Spray services. Electrostatic application of disinfectants, done properly, can help slow the spread of contagious illness, improve health and reduce absenteeism.

Some examples of possible financial consequences of poor sanitation practices:

- Many public schools are subject to attendance based funding policies that penalize schools when students are absent. When teachers are sick, substitutes teachers weigh on school budgets.

- Employee sick days cost businesses $226 billion per year in lost sales and productivity.

- Food Processing Operations and Restaurants can incur crippling financial losses if outbreaks of salmonella, e-coli, or norovirus are tied to a particular business. One high profile fast casual restaurant chain lost billions in market value when norovirus and e-coli related illnesses were tracked to a number of their restaurants.

- Healthcare Acquired Infections (HAI’s) are putting heavy financial pressure on hospitals and nursing homes as insurance companies decline to cover these complications.

- Then there is the public’s perception of sanitation in public facilities and businesses they frequent. There is a direct link between public perception of a business and the overall cleanliness of the facility. The fast growing health and fitness industry is an example where sanitation and membership fee rates can be linked.

Below are some examples of situations where BSC’s could offer a value added service.

Locker Room Service: Locker rooms can be a breeding ground for odor causing bacteria. Metal lockers could be quickly E-Spray disinfected inside and out. Hockey locker rooms and equipment are notorious for bacterial odors that could be E-Spray disinfected in short order.

Flu Service: During cold and flu season offer comprehensive disinfecting service to help slow the spread of cold and flu.

Decontamination Service: Norovirus outbreaks or other contagious pathogen outbreaks might result in closing of a facility for deep cleaning and disinfecting.

Allergen Service: Help decontaminate facilities that have high allergen levels such as mold spores and other fungi.

End of Year School Service: During summer break, thorough disinfecting of student lockers, class rooms, weight rooms, equipment, etc.

Bus or Car Service: School buses or fleet vehicles could be disinfected or deodorized with E-Spray.

Deodorization Services: Facilities that require deodorization due to a variety of bacterial odor problems.

Recreation-Fitness Service: Regular service to disinfectant equipment, free weights, lockers, benches, etc.

Restoration Services:

Restoration: Mold and Mildew: Kill mold and mildew and help prevent re-growth after thorough cleaning.

Restoration: Smoke Damage: E-Spray odor counteractants in facilities as the final step in smoke damage restoration.

Restoration: Flood Damage: E-Spray disinfectants as part of the recovery process of flood damaged facilities

Restoration: Crime Scene: E-Spray disinfectant surfaces that have been subject to blood or other bodily fluids.

PRICING….PRICING….PRICING

Now the hard part, how do you price your service competitively and profitably? Things to consider:

Hourly Production Rate: This is probably most important because it is tied to the labor cost. A reasonable place to start is 10,000 sq. ft per hour. Some reconciliation may be in order because of the differences between floor area and surface coverage area and the overall scope of the project.

Scope of Project: Total size of project, single visit (on demand) or regularly scheduled service.

Non-Labor Costs: Include Personal protective equipment (PPE), equipment amortization, transportation to site, clean up tools, disposables.

Products: Recommended disinfectant, santizer, or odor neutralization products can be ready to use (no dilution) or concentrates. Concentrates would be the most economical form of product.

Other Factors to Consider: Project size, one time or ongoing service, equipment (Backpack, or Handheld unit).

More About Electrostatic spraying?

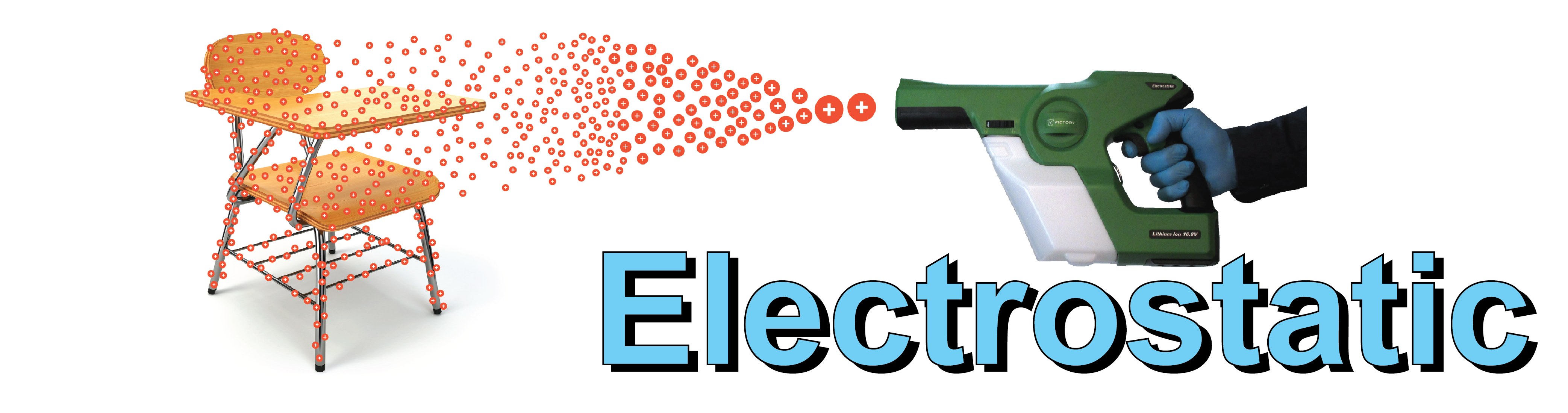

Simply put, electrostatic sprayers apply a small electric charge to liquid droplets just as they exit the spray device. These charged droplets are attracted to surfaces like a magnet, resulting in highly uniform coverage of the spray. Surfaces out of the line of sight are also covered due to the attractive charge applied to the spray droplets.

While this is new technology to the cleaning industry, electrostatic spraying of liquids is widely used and in other industries.

Example #1: electrostatic paint spray systems charge paint particles so that they are attracted to surfaces to be coated. The benefit is uniformity of coverage, drastically reduced overspray, and complex shapes can be coated even if they are out of the line of sight.

Anyone that has ever used a can of aerosol spray paint to paint an object knows that only a portion of the paint actually hits the object.

Example #2: Farmers use electrostatic sprayers to protect their crops from insects and disease. Electrostatic spraying of pesticides on crops results in more uniform coverage and allows for less use of pesticide. Most importantly, the undersides of leaves that would be missed with ordinary spray systems get treated with electrostatic systems.

What makes electrostatic spraying different from other types of sprayers?

When an object is sprayed with a conventional sprayer (including a trigger sprayer), a portion of the spray droplets reach the target object. The rest of the liquid droplets succumb to gravity and fall to the floor or simply float past the object. Further, surfaces of complex objects or hard to reach spots are often missed. These missed spots can be a breeding ground for pathogens.

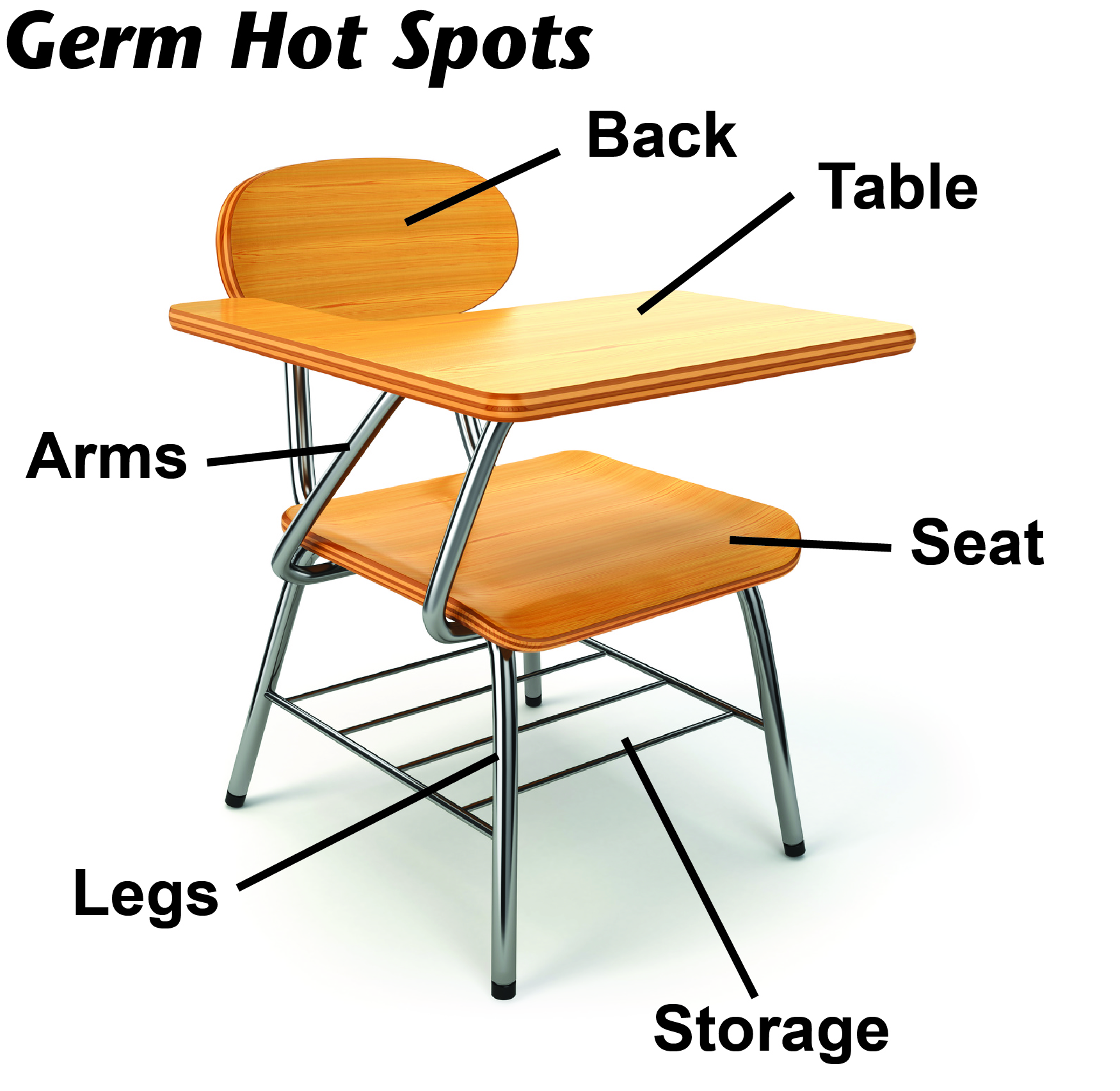

Electrostatically applied liquids have a wrapping effect, so that complex objects and areas hidden from the line of sight get coated with the liquid. Consider a chair/desk, it is easy to disinfect the desk surface, but time consuming to disinfect the underside, the seat, back, and legs. Yet, these are tough points that will see contact with hands.

What are the benefits of using E-Spray in the cleaning industry?

The most important benefit of electrostatic sprayers in the cleaning industry is around the application of disinfectants, sanitizers and odor counteractants.

Validation: It is important that disinfectants and sanitizers used with electrostatic sprayers are validated for use with these devices. For users planning on using an electrostatic sprayer to apply a disinfectant/sanitizer that makes public health claims, it is important to be sure that the germicidal/antimicrobial activity of the product is not compromised. It is important the manufacturer of the disinfectant has evaluated their products for use through electrostatic sprayers by measuring activity of the disinfectants before filling the sprayer and after the disinfectant exits the sprayer.

Disinfectants and sanitizing products that make public health claims must be EPA registered. Manufacturing of such products must be in EPA licensed facilities that follow specific protocols. To insure EPA registered disinfectants and sanitizers are effective on the pathogens listed on the product labels, manufacturers of disinfectants and sanitizers must test the activity of each batch of disinfectant/sanitizer produced. Records and batch samples must be retained for future inspection.

Is there a way to quantify savings with E-Spray?

While difficult, one way to estimate savings based upon data related to absenteeism due to illness. Calculators are available that show potential cost savings of E-Spray Technology in education by using lost revenue from student and teacher absences. In business, similarly, one can use absentee rates to quantify financial impact on businesses.

E-Spray POWER SOURCES: The electrostatic sprayers require a power source to charge the liquid particles and propel them toward the target objects. There are electrostatic sprayers on the market that use a cord to plug into 120V outlets, and portable units that use rechargeable lithium ion batteries.

What do you have to remember with Electrostatic Sprayers?

It is not a substitute for wiping/cleaning of high touch surfaces.

It is another tool in the arsenal against the spread of contagious illness.

Learn More: www.multi-clean.com

The E-Spray System is sold by Multi-Clean through a network of authorized distributors. The E-Spray System includes the portable E-Spray Hand Held and Backpack electrostatic sprayers for use with Multi-Clean brand products that have been validated for use through the E-Spray System.

To learn more, visit our electrostatic webpage: www.multi-clean.com/electrostatic/