Electrostatic Spray Disinfecting: Developing E-Spray procedures to do it properly

Electrostatic spray disinfecting during the corona virus pandemic has become all the rage. Proper E-Spray Disinfecting starts with having documented procedures outlining the entire process. This post dives into the development of standard operating procedures for electrostatic spray disinfecting with the Multi-Clean E-Spray Electrostatic Sprayers.

STANDARD OPERATING PROCEDURES: E-Spray Disinfecting

Purpose: Define a protocol for a process of disinfecting non-porous surfaces using electrostatic spray equipment.

Scope: Proper disinfecting of surfaces requires an understanding of the process that takes into account application procedures, disinfectant contact time, dilutions, pathogens of concern and coverage rates. This SOP is specific to the use of Electrostatic Spray Equipment manufactured by Victory Innovations for application of EPA registered disinfectants.

Definitions: Common Definitions of terms used throughout.

EPA: Environmental Protection Agency: An agency of the U.S. Government that is responsible for regulating pesticides. Disinfectants are referred to as “Antimicrobial Pesticides” by the EPA.

EPA List N: Disinfectants for use against SARS-Cov-2, the cause of COVID-19. A list of disinfectants including those with efficacy toward previously known human corona viruses, those with an Emerging Viral Pathogen Claim, and those for demonstrated efficacy toward SARS-CoV-2 (the virus that causes COVID-19)

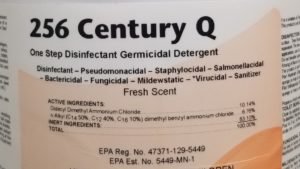

EPA Registration Number: xxx-xx-xxxx The first 2 sets of numbers defines the primary registrant and formula. The last four digits represents the EPA establishment number that can manufacture, package, and distribute the formulation under a company’s own brand name.

Hospital Grade Disinfectant: Disinfectants that have minimum efficacy claims for Pseudomonas Aeruginosa, Staphylococcus Aureus, and Salmonella.

EPA Emerging Pathogens Policy: A policy of the Environmental Protection Agency to address previously unknown pathogens. The policy allows licensed products to make off label claims of disinfection against a previously unknown (emerging pathogen) pathogen if the product has claims for a harder to kill pathogen.

Disinfectant Contact Time: The time with which the disinfectant should remain moist on a surface to kill a specific pathogen.

Spraying Devices: These devices typically have wet droplet sizes of 40 microns or greater.

Fogging or Misting Devices: These devices have wet droplet sizes of 5-15 microns.

Electrostatic Sprayers “Targeted Spraying”: Low pressure devices capable of spraying a disinfectant in droplet  sizes ranging from 40 to 110 microns. These devices are based upon established industrial technology and work by applying a positive electrical charge to spray droplets that cause the droplets to be attracted to oppositely charged or neutral surfaces. This results in more uniform surface coverage and the ability to wrap around surfaces and complex shapes. The targeted spraying using E-Spray equipment means less airborne droplets, less over-spray, and better coverage of surfaces.

sizes ranging from 40 to 110 microns. These devices are based upon established industrial technology and work by applying a positive electrical charge to spray droplets that cause the droplets to be attracted to oppositely charged or neutral surfaces. This results in more uniform surface coverage and the ability to wrap around surfaces and complex shapes. The targeted spraying using E-Spray equipment means less airborne droplets, less over-spray, and better coverage of surfaces.

Equipment: E-Spray Backpack and Hand Held Units

E-Spray Backpack: Electrostatic sprayer powered with a re-chargeable 16.8V Lithium Ion Battery with a tank capacity of 9 quarts (2.25 gal) of disinfecting solution. Includes a 3-position spray nozzle to adjust spray droplet size to match disinfectant contact times. For more details including set up, click here.

E-Spray Hand Held: Electrostatic sprayer powered with a re-chargeable 16.8V Lithium Ion Battery with a tank capacity of 1 quart of  disinfecting solution. Includes a 3-position spray nozzle to adjust spray droplet size to match disinfectant contact times. For more details specs, click here.

disinfecting solution. Includes a 3-position spray nozzle to adjust spray droplet size to match disinfectant contact times. For more details specs, click here.

Disinfectant Chemicals

Types: Consumer products sold in retail stores are designed for consumer/home use. Commercial disinfectants are usually hospital grade disinfectants and specifically state “For Commercial and Industrial Use Only” on the labels. Disinfectant products that make public health claims (kills pathogens) must be registered with the EPA and have an EPA registration number unique to the product.

Efficacy Claims: Disinfectants must clearly state which pathogens the product is effective against. These pathogens must be listed on the EPA approved label on the product. In addition, this label must state the EPA reg number, active ingredients by name and % in the product, specific use, disposal instructions, and name/address of the manufacturer/distributor.

Emerging Virus Pathogen Claims and Efficacy Against Human Corona Virus that causes COVID-19.

With the concerns about the virus that causes COVID-19, some disinfectants have EPA approved Emerging Virus Pathogen Claims. This EPA policy is intended for addressing newly discovered pathogens not previously known. Case in point is the Virus that causes COVID-19, which is named SARS-CoV-2. This human corona virus is an emerging pathogen. The EPA policy states that if a disinfectant has an efficacy claim for one or more harder to kill pathogens than the emerging pathogen, then a disinfectant can make a claim that the product is effective on the specific emerging pathogen, in this case SARS-CoV-2. Disinfectants for use against SARS-CoV-2 can be found on EPA List N: Disinfectants for Corona Virus (COVID-19). Those disinfectants with Emerging Virus Pathogen Claims are differentiated from disinfectants with only claims against previously known human corona viruses.

Multi-Clean offers a variety of hospital grade disinfectants that have emerging virus pathogen claims and therefore are effective on SARS-CoV-2, the cause of COVID-19. For more information on these disinfectants, click here

Frequency of Disinfection with Electrostatic Sprayers

Frequency of E-Spray disinfection will take into account seasonal factors (flu season, pandemics), traffic counts, high touch point surfaces, social distancing strategies, and area/room turnovers. Note that high touch surface disinfecting is ongoing and complements E-Spray Disinfection.

Example: Schools

Classrooms: A school may have to make a decision to E-Spray Disinfect anytime their is a change over in student in a particular classroom. While many schools are reducing class change over frequencies to deal with this, it would be advised to utilize E-Spray disinfecting between classes. Otherwise, classrooms at minimum should be E-Spray disinfected as an end of day routine.

Buses should be E-Spray disinfected each time the bus is emptied of students and before starting a new route.

Cafeteria’s should be E-Spray disinfected after each group of students completes breakfast/lunch.

E-Spray Disinfecting Process

Preliminary

- Charge Battery: Place battery on charger when project is complete. Re-charge

time is about 3 hours. Remove from charger and insert into the unit. - Dilute disinfectant in accordance with the directions on the label. Note it is a

violation of federal law to use a disinfectant that is inconsistent with label instructions.

Concentrated disinfectant must be measured accurately and only mixed with water.

Do not mix with other cleaning compounds. Use a measuring cup. Alternatively, some

disinfectant packaging allows for accurate measurement with a built in squeeze and

pour OR through an automatic dispensing system to obtain precision dilutions. - Filling Reservoir: Fill reservoir of E-Spray unit only with the properly diluted

disinfectant. - Comply with OSHA Secondary Labeling Requirements: Apply a label to the reservoir with a secondary label identifying the diluted product and any potential hazards associated with the products. This is OSHA mandatory.

- Set the Spray Nozzle: Select the appropriate droplet size on the adjustable

color coded nozzle to 80 microns (GREEN) for disinfectants with a 10 minute contact time or 40 microns (RED)for disinfectants with a contact time of 5 minutes or less.

- PPE: The Technician conducting disinfection should wear a dust/mist mask (N95 or

equivalent), eye protection and disposable gloves. Anyone in the area should wear PPE or be at least 20 feet away from the Technician.

Application: E-Spray Disinfecting

Step 1: Prepare the area

Pre-Cleaning of Soiled Surfaces: Surfaces that are visibly soiled require a precleaning

step. Remove debris by wiping with a cloth moistened with an appropriate

cleaning product.

Cover or stow food items: Any food items should be stowed away or covered prior

to E-Spray disinfectant application.

Paper: Consider removing paper products from the area to be treated.

Place Signs or warning indicators: Place signage or secure area to keep bystanders outsidethe treatment area while E-Spray disinfection is in progress.

Step 2: E-Spray Disinfection Application

1. Be sure electrostatic switch is in the ON position. Standing with the sprayer nozzle approximately 1–2 feet away from surfaces, spray individual surfaces and objects, working from high to low areas using a side to side motion until surfaces are covered with  disinfectant.

disinfectant.

2. When using the Multi-Clean disinfectants, spray surfaces to ensure visible wetness for the desired contact time. Allow surfaces to air dry.

3. Wiping or rinsing is not required after E-Spray disinfection in most cases; however,

you may choose to wipe specific surfaces to polish them (e.g., glass, mirrors) or to

remove visible residue after the contact time is achieved. Primary food preparation

surfaces must be rinsed with potable water after the specified contact time. In Daycares, “mouthed” toys should be rinsed after the appropriate contact time is achieved.

4. Occupants can enter and use the area after all surfaces are dry, about 15 minutes after spraying has been completed.

Step 3: Completion and System Maintenance

• Open area to traffic after surfaces dry (15 minutes).

Perform System Maintenance

• Empty Reservoir: Do not store unit with disinfectant in tank.

• Fill Reservoir with water and attach to sprayer.

• Activate unit and spray for 5 seconds to flush unit, then empty tank.

• Weekly: Remove nozzle, rinse with water, then re-install.

• Monthly: Remove nozzle, soak in delimer or white vinegar for two hours to remove

hard water residue.

E-Spray Disinfecting with electrostatic sprayers is another tool in the infection control tool box. As businesses, schools, and other public spaces re-open, cleanliness and the process to achieve cleanliness will be scrutinized. Understanding how E-Spray disinfecting fits into an overall infection control strategy will help insure employees, students, staff, visitor and customers feel confidently SAFE.

Please visit our Electrostatics webpage to get more information. https://www.multi-clean.com/electrostatic/

This is a fantastic website , thanks for sharing.

It’s great to know that using electrostatic disinfecting sprays could reduce airborne droplets and provide better coverage for the surfaces. My wealthy uncle is thinking of opening a coffee shop in town soon. If he opens one next year while COVID-19 is still a threat, I’ll suggest investing in an e-spray backpack. Thanks!